Products

EGR

(Electrolytic Grinding Reducing)

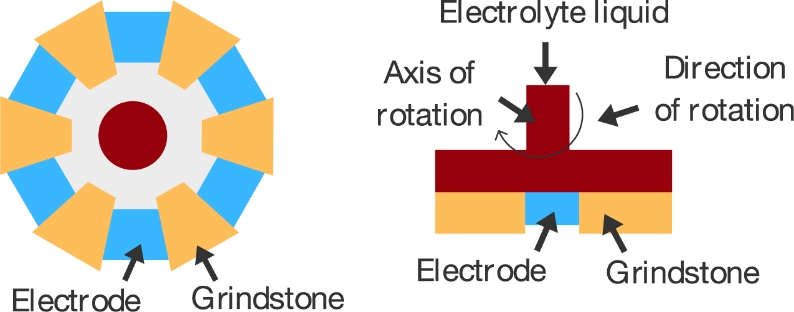

Electrolytic Polishing is intended for precision polishing in general, but our original Electrolytic Grinding Reducing system (EGR) performs much better in area reduction result.

Unlike the traditional concept of a polishing, we provide excellent quality of finishing while reducing prices.

EGR (Electrolytic Grinding Reducing) is our original foundation polishing technology which have high standing for reduction of environmental impact, improves efficiency and variety.

Reducing environmental impact

- Better dust handling than a conventional grinding machine.

- Better sludge handling.

- Descalable without using strong acid.

Improve the efficiency of surface skin

- By using Hot-Rolling black lebeller, shots, pickling and belt polisher can be omitted.

- Improves the quality of finishing process.

Variety of the skin surface

- Area reduction of approximately 30μmt in one path.

- Smooth skin surface as cold-rolled material.

Ability

- Thickness

- 4mm or more

- Width x Length

- 2500mm or less x 8000mm or less

- Electrolyte

- 30% NaNO3 (Flow velocity: 5~10m/s)

- Current density

- 5~40A/cm2

- Head rotation speed

- 300~600rpm

Technology

Acquired Patent

- Japanese patent registered from 2011 to 2016

- EP patent registered from 2014 to 2018

- Chinese patent registered in December 2016

- Korean patent registered in August 2018

Received the 37th Technology Development Award from

“The Japan Institute of Metals and Materials”.